Reflow ovens

The reflow soldering systems from SMT Thermal Discoveries stand for maximum efficiency and high product throughput with stable soldering quality. The parameterization of air flow with continuously adjustable fan units and a uniquely innovative heating zone concept enable a process-optimized soldering profile that can be flexibly applied to different products with constant temperature settings.

| Category | Reflow ovens |

|---|---|

| Our solution | Inspection and production in SMT |

| Supplier | SMT Thermal Discoveries |

Main features and benefits of the device

- The unique heating zone concept guarantees the lowest energy and media consumption

- Reduced, tool-free maintenance effort

- Extended maintenance intervals

- Optimized process gas cleaning

- Stable cooling performance thanks to the smooth/flat cooling plates

- Exact nitrogen control through integrated lambda sensor technology

- Process stability through monitoring software

- Fan units are gas-tight and maintenance-free for life

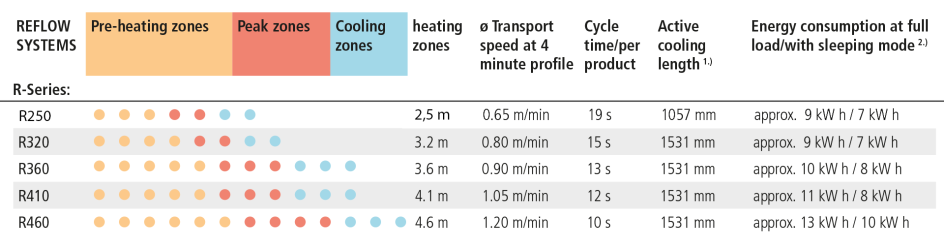

System models

Related categories

Pore-free soldering is a basic requirement in high-performance electronics.

We offer 3D AOI (Automatic Optical Inspection) by the world’s leader Koh Young. The Koh Young AOI machines are unique with their 3D technology...