Vacuum-Reflow ovens

Pore-free soldering is a basic requirement in high-performance electronics. Life support devices, the control technology in aircraft and the driving assistance system in the automobile sector all have one thing in common: they must function absolutely safely and error-free for many years. One condition for this is an almost pore-free solder connection. Pores in a solder joint must be reduced to a permissible minimum.

| Category | Vacuum-Reflow ovens |

|---|---|

| Our solution | Inspection and production in SMT |

| Supplier | SMT Thermal Discoveries |

Main features and benefits of the device

- Pores are reduced by up to 99%

- Suitable for printed circuit boards, DCBs, lead frames and workpiece carriers

- Powerful vacuum pump (300 m³/h) fast and reliable vacuum process

- Profiles can be set with and without vacuum

- Parameters can be set individually: evacuation time, vacuum holding time, ventilation time, vacuum pressure

- Stainless steel vacuum chamber

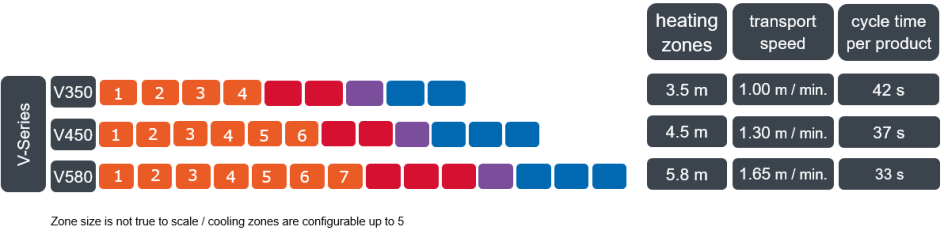

System models

Related categories

The reflow soldering systems from SMT Wertheim stand for maximum efficiency and high product throughput with stable soldering quality.

We offer 3D AOI (Automatic Optical Inspection) by the world’s leader Koh Young. The Koh Young AOI machines are unique with their 3D technology...